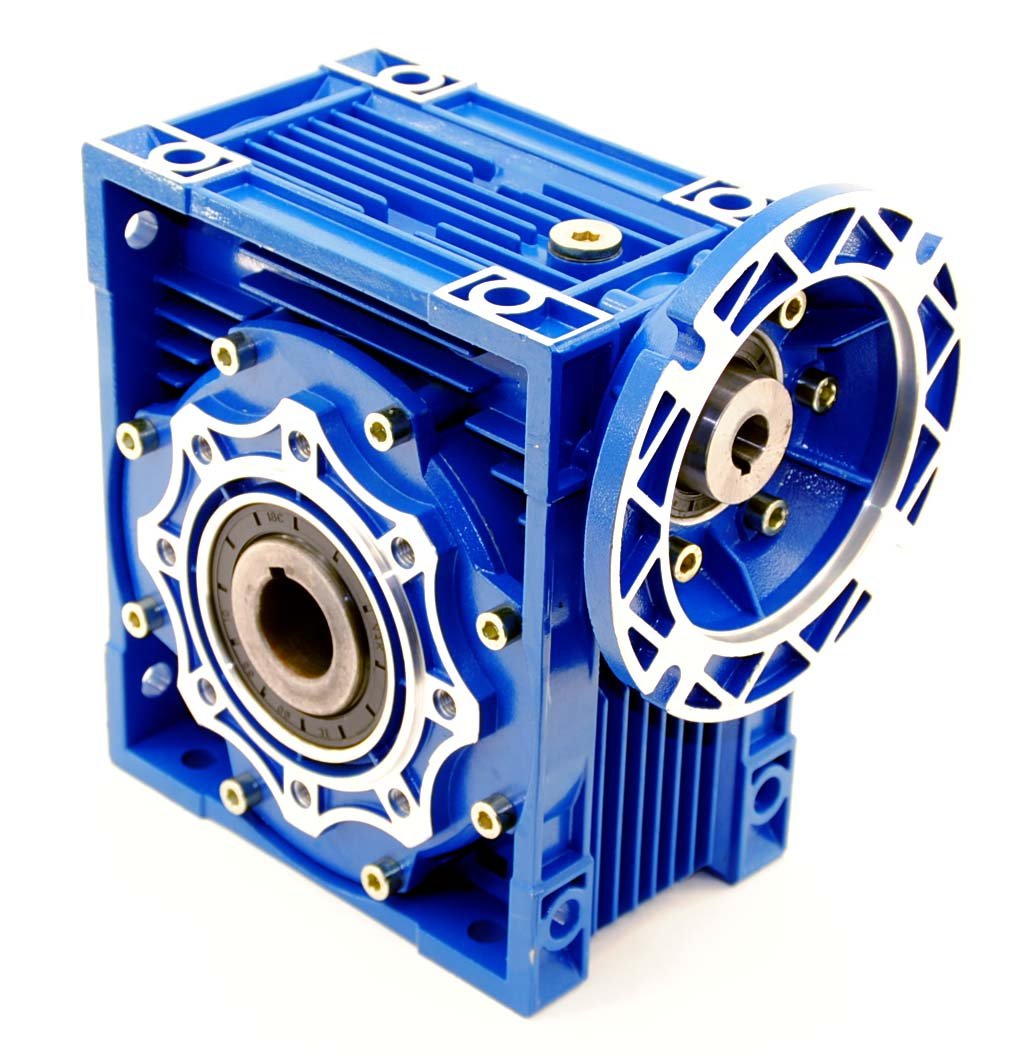

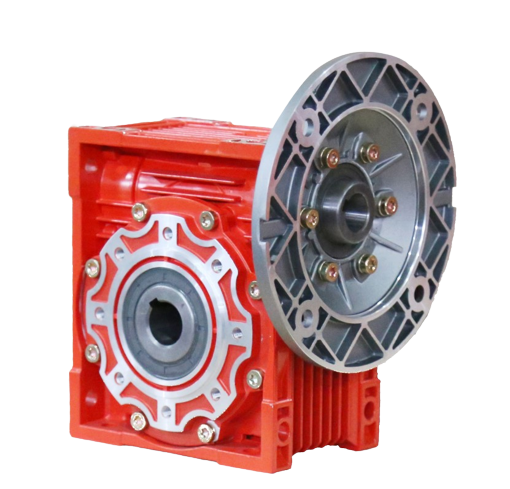

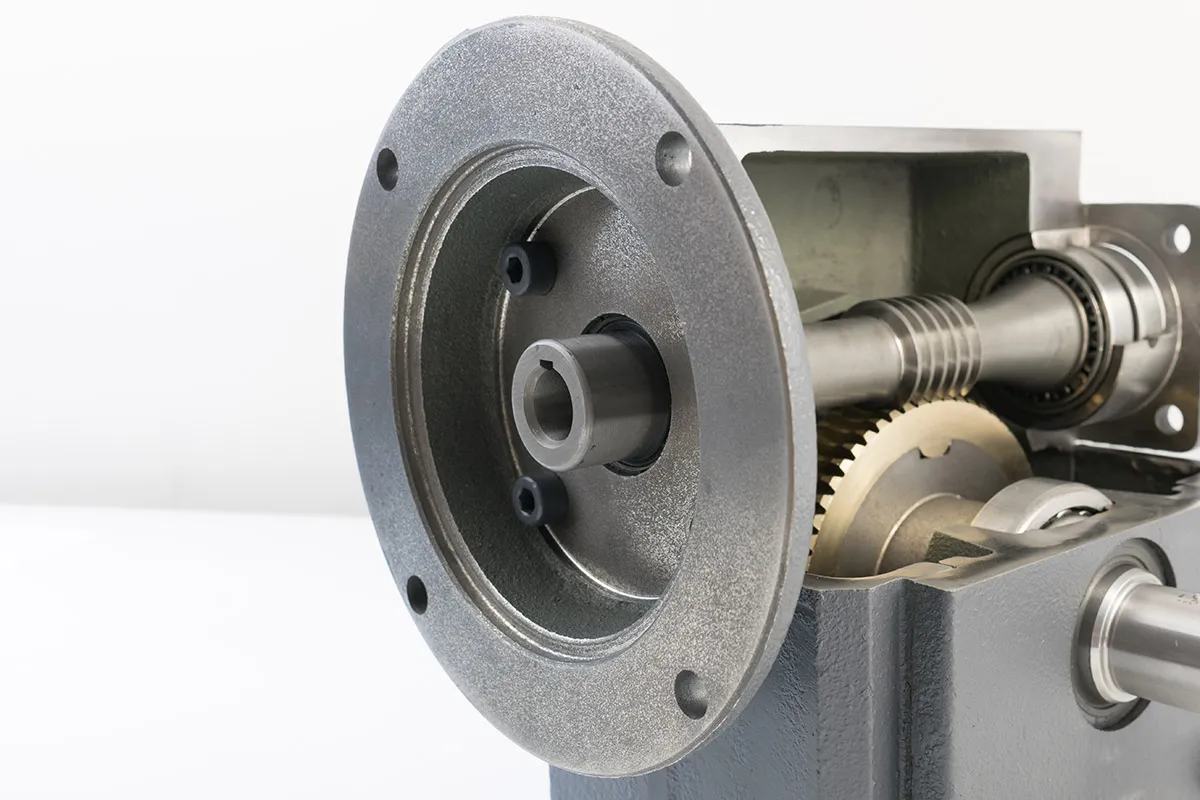

Worm Gear Reducer

As the name suggests, a worm gearbox is a box that houses a worm gear. It is also often referred to as a worm gear reducer, and these terms essentially refer to the same thing. A worm gear box functions like any gear system in that it increases torque and reduces speed between a driven device (such as a motor) and a load.

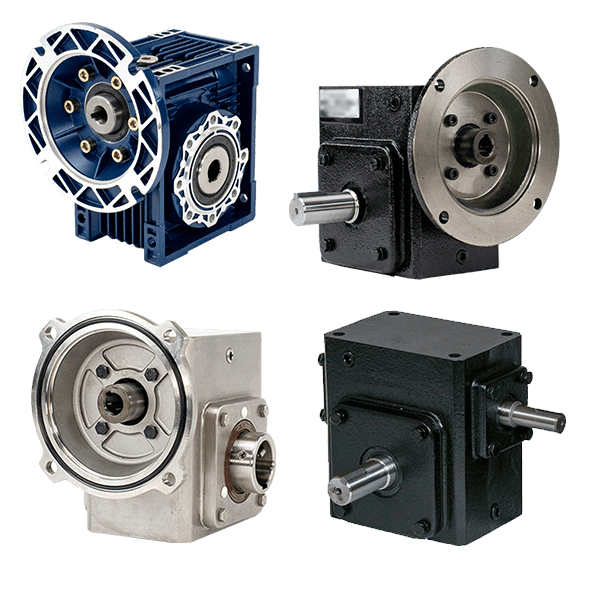

Our Products

If you need a customized product, or the product you need is not found on our website, don’t worry, more of our products are still being uploaded. You can contact us directly by email, we will reply to you within 24 hours!

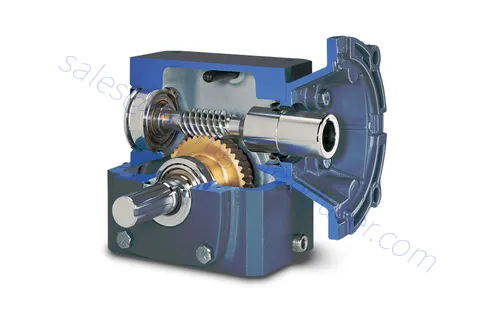

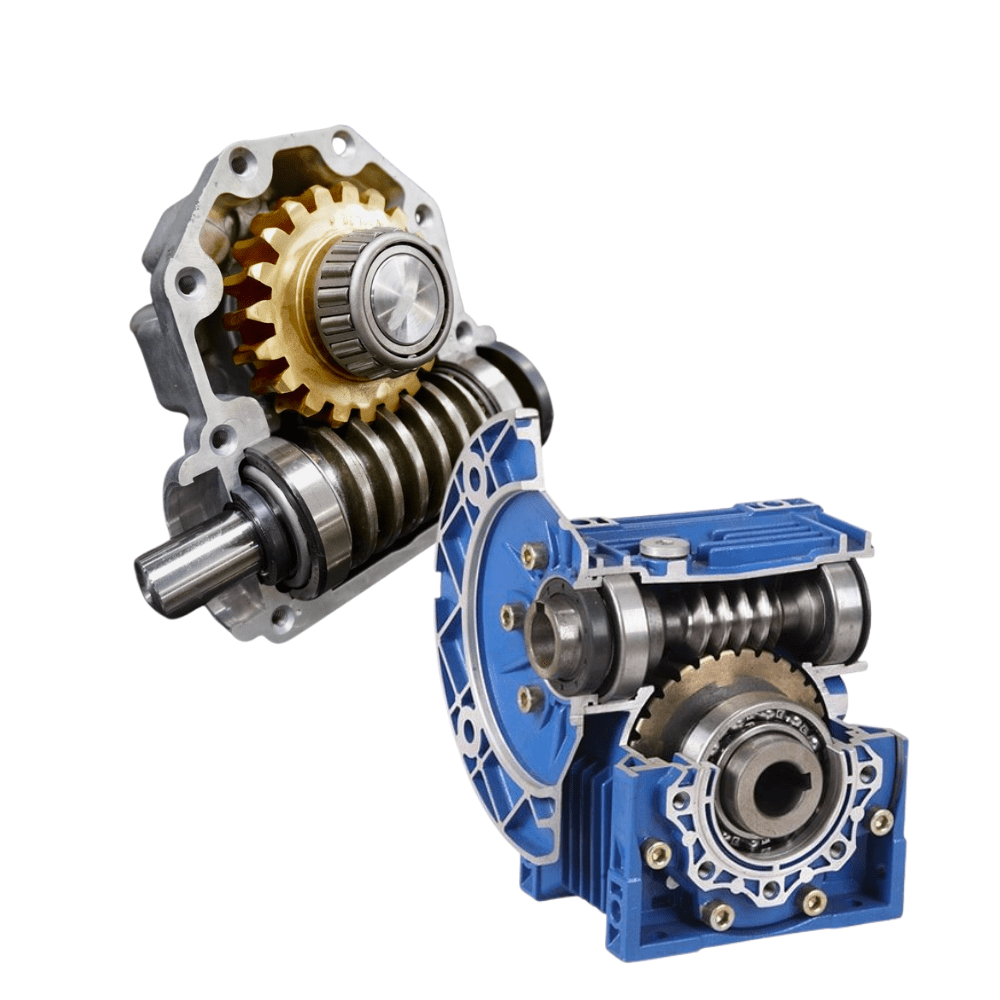

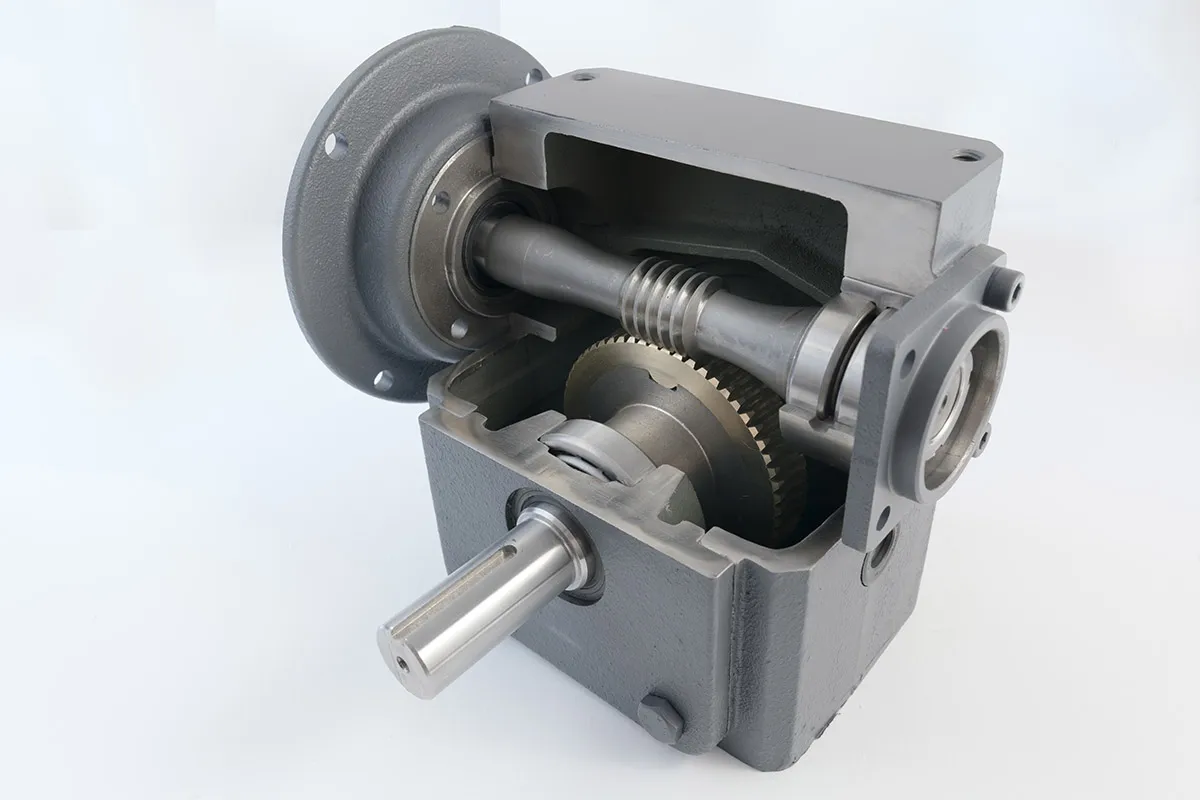

How Does a Worm Gear Reducer Work?

The worm pinion is the screw used to input power to the assembly. When combined with a standard spur gear (called a worm gear or worm gear) arranged vertically with slightly sloping teeth, the pairing becomes a worm gear reducer. When power from the engine or electric motor turns the worm pinion, its helix pushes the teeth on the worm wheel, causing it to turn at the designed reduction ratio when a load is applied to the drive shaft.

Higher reduction ratios can be achieved by increasing the circumference of the worm gear or increasing the number of threads on the worm pinion. Achieving the same reduction with a traditional gear set requires multiple reductions, which take up more space. Increasing the part count increases cost and increases the risk of component failure.

FEATURES

- Available for both IEC and NEMA motors.

- Range of ratio is from 1/5 to 1/3600.

- Range of horse power is from 1/4HP up to 100HP.

- Applied premium quality double-lip oil seals.

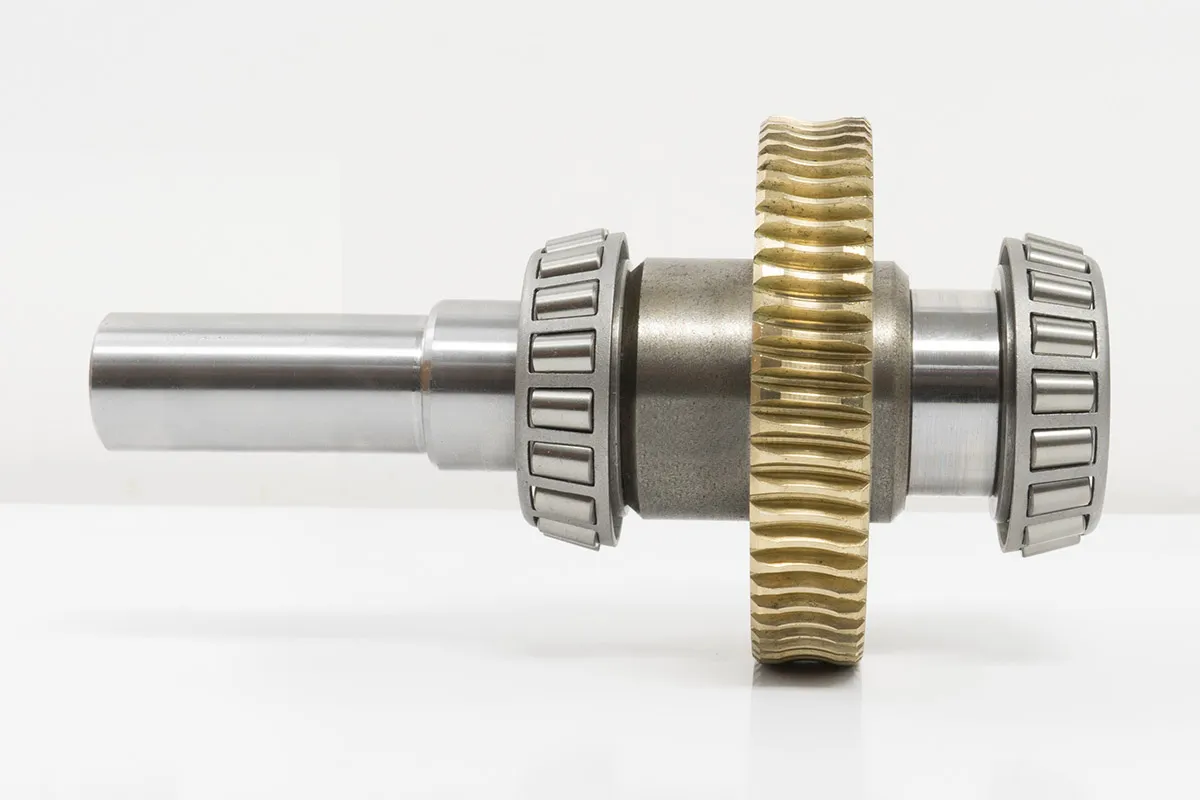

- Medium Carbon Steel (S45C) worm shaft with harden heat treatment and grinding on threads.

- Chromium Molybdenum Alloy Steel (SCM440) worm shaft with high frequency heat treatment and grinding on threads for box size 300 to up.

- Aluminum Bronze (ALBC3) wheel for a better durability.

- Robust housing made in Grey Iron (FC20) and Ductile Cast Iron (FCD45) for box size 300 to up.

- Removable base for universal mounting gearboxes.

How do you find the right size and style?

Determine the correct size and style of reducer by analyzing specific application requirements and project specifications. Our experienced support staff is ready to help you select the correct reducer for your application!

Contact us for information on any of our reducers or to request a quote for a custom reducer.

Advantages of our Worm Gear Speed Reducers

Minimal oil leakage and longer seal life

Our metal-reinforced, spring-loaded, double-lip oil seals are mounted on shafts with grounded seal seats to minimize oil leakage and provide longer seal life.

High-strength shafts with ground-bearing housings extend bearing life

Our one-piece shafts are made of heat-treated alloy steel for high strength. We use centerless ground housings to provide an ideal shaft fit and extend bearing life.

Protects against wear and corrosion

Our products use cast iron housings with a highly corrosion-resistant finish and a spacious oil sump. These features dampen the effects of vibration and shock, protect against corrosive elements, and provide ideal lubrication throughout the life of the equipment.

compatibility

We use cast iron NEMA C input flanges, making our reducers compatible with most off-the-shelf electric motors.

High load capacity

We use tapered roller bearings on the output shaft to give our reducers high overhung and thrust load capacity.

Arrangement options

Our X-Series gearheads are available in a variety of input and output shaft configurations, making them easy to use in many applications.

lubricating

The oil contained in the housing oil tank is splashed into the worm bearing and tooth contact area. (The gear bearings are grease lubricated at the factory and require only occasional attention.) The oil level should be maintained properly. In accordance with best practice, it is recommended to completely change the oil every six months after normal service. Oil seals are installed on all shaft extensions. A “dry well” is standard equipment on larger units to ensure a vertical positive seal under the shaft extension. Inspection holes are available for packing plugs, drain holes, vent holes and all mounting arrangements. Lubricant types and oil capacities for each size and type of reducer can be found in the Operations and Maintenance Manual shipped with each unit, or can be found on our website. The oil level should be kept at a height determined by the oil level with a sight gauge or inserted into the reducer casing, and only check that the reducer does not work in the following cases.

Email Us

Our services include:

● 24-hour breakdown service.

● Gearbox or component repairs in our in-house and well-established machine shop.

● A dedicated team of in-house sales engineers assists our customers with all transmission issues.

● Create sustainable partnerships with high-quality and cost-effective units for all applications.